Land Stabilisation Systems

Reclaiming / Mixed in Plant

.

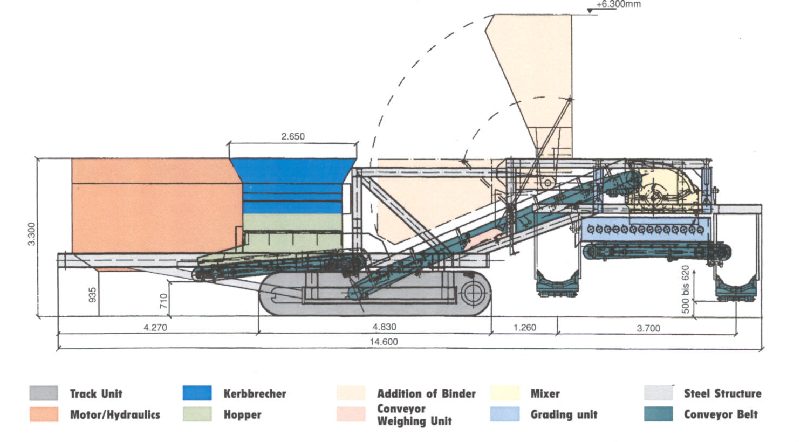

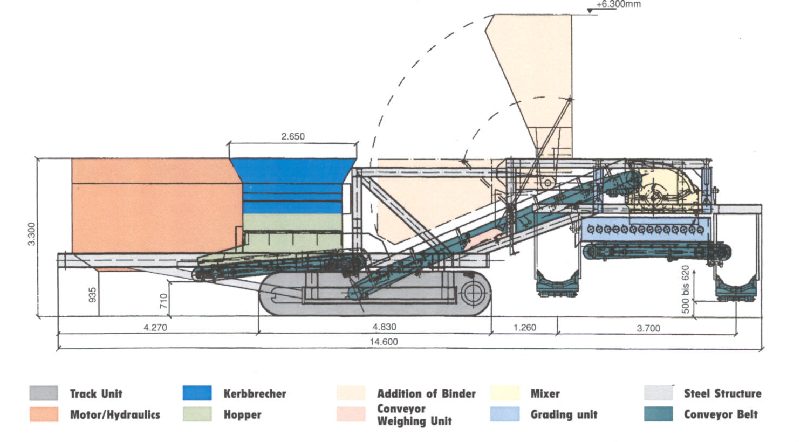

Mobile land preparation system with special-breaker, binder additive unit, mixer and grading unit for the preparation of cohesive and muddy mineral mix material.

A modern, robust built, fully mobile land preparation system for processing 150- 250 t/h with input fragment sizes of up to 1.000 mm in length 300mm thickness, depending on the type and properties of the material to the processed and the desired grade of soil.material flow and main system components:

· loading system - the material to be processed is loaded directly into the the breaking-unit

· reversible breaking unit with interchangeable tools, to change the grade of the end product in order to produce cohesive mineral compund material

· breaking unit transfer directly on the hopper outlet conveyor

· dosed transfer of the material from the conveyor belt to the conveyor weighing unit

· low maintenance, reversible conveyor belt for a flow of material free from interruptions and blockages

· additives:

- precisely dosed addition of binder· large hopper for binder, integrated in the system. dust extraction and automatic filling possible

- controlled by a Siemens PLC and a conveyor belt weighing unit

- dosing capacity for binder from 0- 20 t/h

- fine-particle binder

- coarse-particle binder up to 2 mm/font>· transfer of the mixed material to the mixer, the mixer transfers the material directly to the grading unit

· adjustable and automatically levelled end product grading unit

· the grading unit sorts the processed material into coarse and fine grade end product, separation up tp 60 mm

· retractable conveyor belt for (coarse grade) end product I für (Überkorn) Fertigprodukt

· retractable conveyor belt for end product II für Fertigprodukt II

· tracked undercarriage

· diesel-hydraulic driving unit

· eletronic control of process and binder dosing

· remote control of processes and operation

· software for feedback on daily productivity, remote data retrieval possible

technical data:

length/ breadth: approx. 14.600 x 3.000 mm · transport-high: approx. 3.300 mm · working-high: approx. 6.300 mm · transportweight: approx. 48 to

diesel-Hydraulic unit: ca. 260 kW · electro-unit: ca. 70 kW · machine work autarkic from elektro installation

adjustable grade of end-product:

end-product I: approx. 15/60- x

end-product II: approx. 0- 15/60 mm

The uninterrupted material flow capabillity and the high performance crusher are distinguishing features of material preparation using our mobil "mixed in plant" unit

a) the crushers design means that the material to be processed can be loaded directly into the breaking unit, guaranteening a uniform flow of material.

b) the crushing tools are interchangeable and can be adapted to the type of material to be processed.

c) processing is possible while the plant is in motion, for continuous heap up the material.

d) no damage by troubeling material

e) no blocking by muddy material

klick here for detailed pictures and videos